Synthetic fibre slings or 'soft' slings are regularly used in workplaces for the lifting and moving of loads by cranes.

Damaged slings can compromise the safety of lifting activity. We have received reports of damaged slings being used.

While synthetic fibre slings may have certain advantages over wire rope and chain slings, they are susceptible to damage and can be cut if exposed to unprotected sharp edges or corners.

Slings can be damaged or fail due to:

- undersized sling capacity

- any visible defect or damage which can reduce the sling’s working load limit (WLL) and possibly become an initiating point for failure

- use of excessive choke

- incorrect slinging techniques, including excessive angles between legs of slings

- inappropriate selection of slings in relation to the load size or shape

- use of synthetic slings without a protective sleeve

- poor storage and harsh environmental conditions.

Sling selection

Always have a range of sling types and sizes available so the correct sling can be selected for the job. An assessment must be undertaken before making a sling selection.

If the load lift is not pre-planned, the person deciding on correct sling selection must hold a Licence to Perform High Risk Work for dogging or rigging.

Use chain or wire rope slings where loads have sharp edges or attached components such as cleats. Synthetic slings must not be used unless protective sleeves are fitted.

Lifting loads

Slings must be slung or reeved as per manufacturer’s instructions or labels.

Never exceed the working load limit of the lifting configuration (hitches). The working load limit will depend on the included angle between the legs of the slings or, in the case of choked hitch or basket hitch, the angle of the hitch. Avoid an included angle exceeding 120 degrees.

Protecting the surface finish or paintwork of the load should not be primary factors in sling selection.

Protection can generally be achieved by fitting engineered lifting points during manufacture or having suitable packing materials between the sling and load when using chain or wire rope slings.

Cut protection

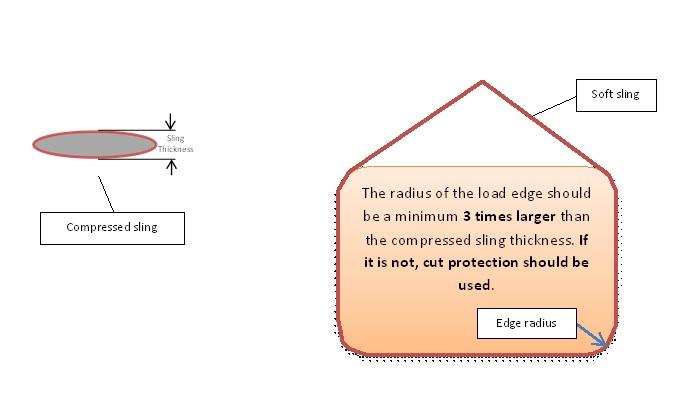

To protect against cutting or localised damage, loads that have corners with a radius of less than three times the compressed thickness of the sling shall be provided with cut protection.

Where corners have a radius of less that the compressed thickness of the sling, the protection, under load, shall increase the radius to at least the compressed sling thickness.

Maintenance and inspection

A competent person must inspect slings before each use for any visible signs of damage that could affect their safe use. The person checking the sling must have attained appropriate instruction and training prior to conducting this work.

A competent person must regularly inspect the condition of the sling for continued safe use at intervals preferably not exceeding three months.

Where synthetic slings are exposed to harsh operating or storage conditions, more frequent inspection may be required.

Further information

Australian Standard AS 4497:2018 Roundslings - Synthetic fibre