Mobile elevating work platforms (MEWPs) are mobile items of plant designed to lift or lower people and equipment by a telescopic, hinged or articulated device, or a combination of these, from a base support.

The Mobile elevating work platforms guideline will help you manage the risks associated with this plant. You can request free copies of this guideline to be mailed to you to refer to onsite.

While MEWPs may control work at height risks, the movement of mobile plant introduces new risk. Persons conducting a business or undertaking (PCBU) usually understand the risks MEWPs pose to people on the ground. However, what’s often not fully considered is the increased crush risk to workers from the MEWP platform or within the basket.

PCBUs and self-employed persons must, so far as is reasonably practicable, identify all hazards and eliminate any risks associated with the use of MEWPs in a workplace.

Three types of mobile elevating work platforms

PCBU’s duties

A PCBU must provide workers with reasonable information, instruction, training and supervision to operate the MEWP in all of the foreseeable work situations which may arise.

A PCBU must also ensure that:

- the type of MEWP is appropriate for the task being performed

- the work is conducted safely

- workers are supplied with correct personal protective equipment (PPE)

- the MEWP is safe to use in that particular environment (e.g. structures in the area, proximity to other workers and powerlines, ground surface)

- the MEWP is maintained in a safe condition.

Worker’s duties

Workers must take all practicable steps to keep themselves safe in the workplace and ensure they do not place others at risk of harm. This includes both the actions they take and the actions they don’t take (i.e. not wearing safety gear).

Workers have a responsibility to:

- identify and report hazards as they arise

- follow the safe work procedures and instructions that are in place

- wear any required PPE

- report any accidents or near misses immediately to their supervisor or appropriate person.

Safe work practices when using MEWPs

Use appropriate equipment for the task

Consider each task and any potential hazards (e.g. indoors or outdoors, presence of overhead hazards, condition of supporting surfaces) and select a MEWP that is suitable to the task. It may be appropriate to use an alternative, like scaffolding, to reach and carry out the task.

Before selecting a MEWP undertake a thorough task, site and equipment specific hazard identification and risk assessment. This may include consideration of the height, reach, crush or trapping hazards, safe working load, ground conditions and terrain, restricted working space and any electrical hazards, including overhead powerlines.

Identifying risks

Fatal incidents and serious injuries may occur when operators and/or passengers are crushed against structures while using self-propelled boom and scissor-type MEWPs.

Crush risks: There is an increased risk of crush to operators or passengers when the MEWP is used near or adjacent overhead or fixed structures.

The likelihood of a crushing incident increases in direct proportion to the number and proximity of fixed structures, such as roofs, cable trays and pipework near the MEWP basket.

Basket stability: The basket moving unexpectedly may be due to unstable ground conditions, an operator’s lack of familiarity with the MEWP’s model-specific controls, or malfunction of control.

Ground-based obstacles: While travelling or maneuvering the MEWP, ground-based obstacles in close proximity to the MEWP may divert an operator’s attention away from overhead or adjacent structures or their passenger’s safety.

The more time spent in a MEWP close to fixed structures, the more likely a crush incident may occur.

Controlling risks

Guide to managing the risks of elevating work platforms

The range of motion available on some modern MEWPs, such as the ability to move into and between structures, increases the likelihood of a crush incident occurring. Before operating a MEWP in, around or near fixed structures, PCBUs must eliminate crush risks where practicable to do so. If this is not possible, risks must be reduced by:

Substitution

Assess the task and consider if the task can be done using an alternative, such as a scaffold instead of a MEWP.

Engineering controls

Operator protective devices

Where an increased risk of workers being crushed against a fixed structure has been identified, the MEWP should be fitted with an effective operator protective device.

Operator protective devices are commonly known as ‘secondary guarding’. These devices include:

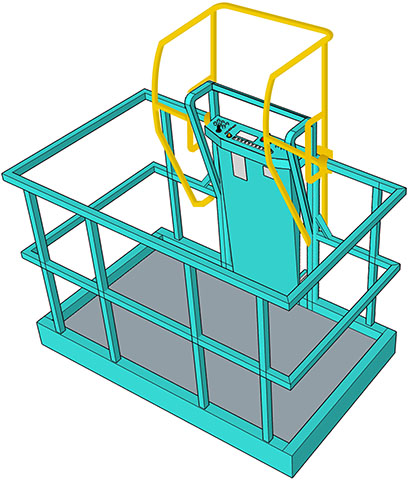

Physical barriers

These barriers are attached to the basket which reduce the likelihood of workers being crushed against structures.

Pressure sensing devices

Pressure sensing devices are positioned over the control panel which detect pending crush incidents and prevent further hazardous movements.

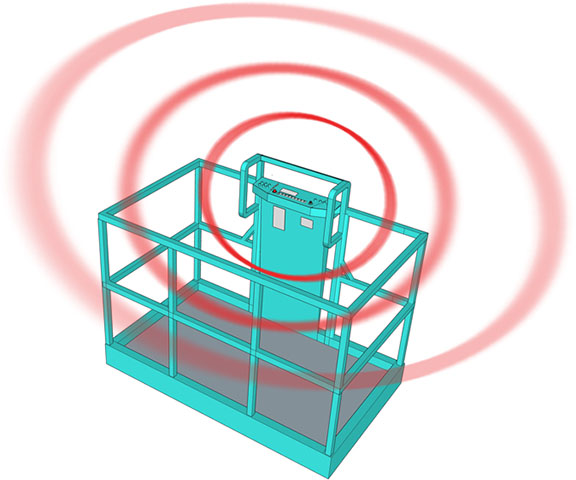

Proximity sensing devices

Proximity sensing devices prevent a MEWP’s basket from maneuvering into crushing proximity of fixed structures.

Standardised controls

When hiring a MEWP or selecting one to use on site, seek out models with standardised controls. Familiarity with a control system contributes to safer operation of the MEWP and can improve outcomes from rescue operations.

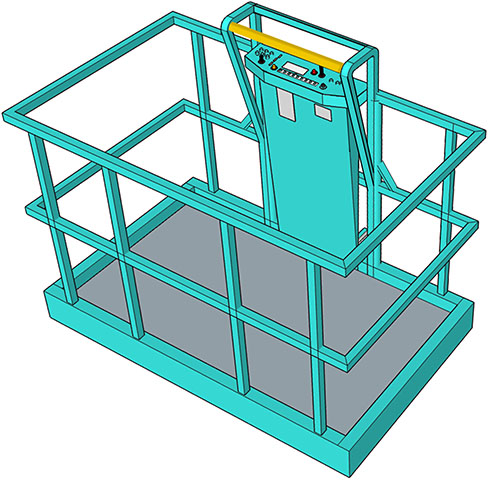

Moveable or remote control box

When using a scissor lift consider one with a moveable or remote control box. Being able to control the plant remotely allows for safer movement of the plant through doorways or where lower overhead structures create a crush risk.

Observers should be used to monitor blind spots for pedestrians when being driven by external ‘umbilical’ control.

Other engineering options

If a MEWP is not fitted with secondary guarding, standardised controls or a remote control box, talk to the supplier about retrofitting options to manage risks of crush injuries.

If you plan to fit a secondary guarding device to an existing MEWP you must undertake a specific engineering risk assessment. This includes consultation with the designer/manufacturer/supplier to determine whether there are any impacts on design registration and to ensure any proposed changes do not introduce new safety hazards or negatively impact the operation of the MEWP. You can contact SafeWork SA for further information about design registration requirements.

Secondary guarding is now available on most scissor and boom type MEWPs.

Administrative controls

Administrative controls will be required to support substitution and engineering controls. Administrative controls should include:

- training, instruction and information

- licensing of operators (if required)

- familiarising operators with specific MEWP model controls, including emergency descent controls

- inspecting and maintaining MEWP consistent with the manufacturer’s instructions

- altering work procedures, including safe work method statements if the MEWP is used in construction work

- providing additional operator supervision

- having MEWP-specific emergency procedures

- having an agreed system of communication with support personnel who have line of sight of the operator

- assigning support personnel who are trained to use MEWP ground-based controls for emergency descent.

Personal protective equipment

Full safety harnesses must be worn by everyone on the platform of a boom-type MEWP and be secured to the anchor point.

Where there is a risk of a free fall, a fall-arrest harness designed for attachment to a lanyard assembly, including a personal energy absorber, must be worn by everyone on the MEWP.

Minimum standard of training

Minimum standard of training and checklist

Before operators start using MEWPs, training must be provided about its functions and any current safe work methods and emergency procedures. There is a minimum standard of training expected for workers who operate MEWPs.

Although the majority of MEWPs are used in construction, this information applies to all industries to ensure the minimum standard of training is being met.

Minimum standard

The minimum standard consists of specific criteria that must be addressed to satisfy the five elements below.

- Plant identification

- Hazard identification and control

- Pre- and post-start inspections

- Safe general use

- Shutdown and post-use inspection

See also: Checklist: MEWP minimum standards of training.

Operator training

Before a worker can operate a MEWP of any type they must be appropriately trained and competent on each type of MEWP to be used.

Nationally recognised training is available from Registered Training Organisations (RTOs) for the various types of MEWPs, including boom-type, scissor and trailer mounted.

A Statement of Attainment for High Risk Work Licence (class WP) training from an RTO is acceptable as proof of training for the operation of a boom-type MEWP.

For a boom-type MEWP, where the boom length is 11 metres or more, the operator must hold a High Risk Work Licence.

The boom length is the greater of:

- the vertical distance from the surface supporting the boom-type MEWP to the floor of the platform with the platform extended to its maximum height or

- the horizontal distance from the centre point of the boom’s rotation to the outer edge of the platform with the platform extended to its maximum reach.

Records of training and operator competency need to be maintained.

Hirers of equipment need to ensure they provide all relevant safety information and should obtain or record verification of operator competency before hiring an MEWP.

For experienced MEWP operators without evidence of training an alternative could be to arrange a registered training provider to confirm knowledge.

Familiarisation training

When operating models different to those used in the training and assessment, the operator should be provided with familiarisation training on the specific MEWP they will be operating. This is due to the design differences between manufacturers and even models by the same manufacturer.

The operator must also be supervised during the training period until they are deemed competent to operate the MEWP.

Training must also be given to other workers within the MEWP e.g. harness use, emergency procedures, overhead structures.

Operators should also receive regular refresher training that covers the minimum standard set out in this document.

Supervision

A PCBU must put in place arrangements for ensuring that a MEWP is used in accordance with safe work procedures by ensuring adequate supervision and monitoring by a nominated competent person.

The use of MEWPs during high risk construction work requires the implementation of a safe work method statement that describes how the control measures are to be monitored.

The person supervising the work activity must ensure there are clear lines of sight and communication while the MEWP is being operated to enable the warning of potential hazards.

Planning the work

Positioning and stability

The position of a MEWP must be carefully assessed, in particular where there are overhead power lines or underground services. Prevailing wind conditions should also be considered. The stability of a MEWP must also be assessed for surface slopes, ground cavities and the condition of the ground surface.

Positioning should be selected to ensure work can be performed adequately from the platform. Workers must stand on the floor of the MEWP only, not on the handrails or items such as ladders, scaffolding or boxes either placed on the platform floor or on the handrails.

The positioning must ensure that access to the emergency descent device is not obstructed and that all operations can be performed within any required exclusion zone.

Support personnel

Personnel on the ground should assist the MEWP operator undertake the job safely and provide a line of sight for the operator to spot any overhead hazards.

Support personnel on the ground are required to:

- aid an operator who is sick or has been injured

- assist if the MEWPs elevating mechanisms fail

- ensure the MEWP doesn’t come in contact with powerlines

- help if the operator is ejected from the MEWP and suspended in a safety harness.

Support personnel must be familiar with:

- the MEWP emergency procedures

- the specific machine being used

- emergency descent controls and rescue devices

- line of sight requirements

- agreed system of communication.

Methods of communication for support personnel include:

- radio communication

- having frequent verbal contact

- hand signaling

- other methods such as whistles.

Base controls

Base controls should not be used when personnel are on the platform except in an emergency or for maintenance purposes. Fit all MEWPs with an emergency retrieval system or provide auxiliary retrieval equipment to enable the safe evacuation of people from the platform.

Operating instructions

Operating instructions must be clearly and permanently displayed on the MEWP.

Wheel-mounted MEWP

MEWPs that are supported on wheels when elevated must be free of damage that may result in instability. Most self‑propelled MEWPs are fitted with solid or foam filled tyres. MEWPs fitted with pneumatic tyres must not be able to elevate without first activating stabilisers. Pneumatic tyres must be free of defects and inflated to the correct pressure.

Safe working load

The total weight of people, tools and material loaded on the platform must not exceed the MEWPs rated load capacity.

Refer to the safe working load decal located on the MEWP.

Overhead structures

Implement a ‘lower-before-travel’ policy where workers must lower MEWPs so they are completely clear of any overhead structures before driving/travelling in the unit.

Overhead powerlines

Extreme caution must be exercised when operating a MEWP near overhead powerlines. The minimum safe distances for operating cranes, machinery, vehicles or vessels with elevating components near powerlines are detailed in the Electricity (General) Regulations 2012.

Work in public places

When a MEWP is used in a public place or on a roadway, suitable barricades need to be positioned to keep pedestrians and vehicles at a safe distance. Warning signs should be displayed and the appropriate approvals obtained from local authorities.

Maintenance and repair

Guide to inspecting and maintaining elevating work platforms - Safe Work Australia

Pre-operational checks

Before use and at the start of each shift a MEWP must be checked by the operator and tested in accordance with the pre-operational checklist based on Australian Standards.

Checks must include safety devices and interlock controls.

If faults are identified, the MEWP must be placed out of action (tagged out) and fixed before being used again.

Maintenance

All maintenance, inspections and repairs need to be undertaken regularly and in accordance with the

manufacturer’s recommendations. A MEWP owner may engage a competent person to ensure this is done properly.

All MEWPs ‘in-service’ should be regularly inspected and must have a major inspection by the end of the tenth year.

Checks must include safety devices and interlock controls. If faults are identified, the EWP must be placed out of action (tagged out) and fixed before being used again.

Checklist: MEWP minimum standard of training

Minimum standard of training and checklist

Any worker operating a mobile elevating work platform (MEWP) should be able to demonstrate knowledge of all the criteria in this checklist. This criteria can be used as a guide when identifying hazards and developing a safe work method statement (SWMS) for high risk construction work.

Plant identification

The worker knows how to identify and, where applicable, understands the key features of the MEWP being used, including:

- access point

- operational controls

- location of the MEWP logbook

- safe operating procedures

- safety-related signage and bunting

- safety or emergency devices (e.g. emergency descent controls).

Hazard identification and control

The worker can demonstrate that they have considered any hazards and the associated risks at the workplace. For example:

- condition of the terrain/operating surface

- ground bearing pressure

- restricted working space

- overhead hazards

- crush and entrapment hazards

- proximity of powerlines and structures

- underground services

- weather conditions

- working height and reach of MEWP

- type, mass and dimensions of loads to be elevated

- access/egress at height

- other people, vehicles or plant in the area

- adequate ventilation in the area where the MEWP is to be used.

Safe general use

The worker:

- understands the hazards and risks associated with the MEWP (e.g. stability, brakes, turning circle)

- knows how to safely operate the MEWP including mobilisation, operation and retraction

- knows the location of all emergency descent controls and understands how to use them

- knows how to position the MEWP to ensure access to the emergency descent controls is not obstructed

- identifies support personnel who will provide line of sight from the ground and have an agreed system for communication

- understands how to set up exclusion zones

- understands their responsibilities to other workers in the MEWP

- knows when a harness is required and how to inspect and ensure correct fitting

- understands the safe work method procedure or SWMS requirements when using the MEWP for construction work

- understands the PCBU’s emergency rescue procedure.

Pre- and post-start inspections

The worker knows how to:

- identify and control the hazards related to the operation of the MEWP they are using

- identify and control hazards associated with the work task and location

- identify hazards where the assistance of support personnel is required (e.g. line of sight of the MEWP and a system of communication)

- identify any reasonably forseeable emergency that could arise and plan rescue arrangements

- conduct a pre-start visual inspection of the MEWP for signs of damage

- ensure all associated safety equipment (e.g. harness and lanyard) is fit for purpose and undertake a visual inspection for signs of damage before commencing work

- check the MEWP’s log book to ensure that the MEWP has been routinely inspected and serviced in accordance with the manufacturer’s recommendations and that there are no outstanding faults or defects (e.g. cracked welds, corrosion, in-operable controls, unclear control panel labelling, deformed structure components, fluid leaks, damaged or defective tyres, harness and attachment point damage)

- operate and is familiar with the control panel and full functions of the MEWP

- correctly set up outriggers, including selection and use of pads

- check the control panel is fully operational by conducting a full range of trial movements

- check to ensure that all warning devices and braking and operational systems are fully functional

- accurately complete the MEWP’s logbook, including the identification of any faults or defects (where found)

- take action to tag out faulty equipment or the MEWP, where necessary, and report it has failed pre‑operation inspection.

Shutdown and post-use inspection

The worker knows how to:

- shut down, retract and secure the MEWP

- conduct a post-use inspection, including the identification and recording of any new faults and defects in the MEWP’s log book

- report any defects and faults, and to whom

- where necessary, take action to tag out equipment or the MEWP if faults are identified during shutdown and post-use inspection.

Further information

Guide to managing the risks of elevating work platforms

Managing the Risks of Plant in the Workplace – Code of Practice

Elevating Work Platform Association of Australia

Mobile Elevating Work Platforms 2019 Audit Report

Mobile Elevating Work Platforms 2020 Audit Report

Using elevating work platforms (WorkSafe QLD)

Safe Operation of an EWP (Master Builders Victoria)

AS 1418.10: Cranes, hoists and winches – Mobile elevating work platforms

AS 2550.10: Cranes, hoists and winches – Safe use, Part 10: Mobile elevating work platforms