Conveyors have many moving parts and potential nip points, which can make them a dangerous item of equipment.

Training

During the training of conveyor operators, each operator must understand the safe operation of the conveyor and all safety precautions, including:

- the method of stopping and starting the conveyor

- the hazards in the course of normal working of the conveyor

- the hazards from bad practices, inattention, and misuse

- the purpose of the guard or safety device, and how the guard or device may fail

- informing the person in charge if any faults or defects arise, and the danger to the operator in attempting to correct any faults.

During the training period, a conveyor operator must be supervised by a worker with a thorough knowledge of conveyors.

Safe operating procedures

The following safe operating procedures apply to all conveyor installations:

- ensure all START/STOP and emergency controls are marked

- ensure persons working near a conveyor are aware of the location of START/STOP and emergency controls

- keep the area clean and tidy. Good housekeeping eliminates hazards such as tripping, slipping and falling

- isolate and danger tag the power source before working on a bogged or overloaded conveyor

- ensure all persons wear appropriate clothing and avoid loose clothing near moving conveyors

- ensure conveyors are guarded/fenced (if not a walk-under conveyor)

- do not clean belts, pulleys, drum, trough or return idlers while a conveyor is moving

- do not ride on a moving conveyor

- do not repair or maintain a conveyor while in motion. If repairs, adjustments or tracking are required on a moving conveyor belt without normal guarding, it is important that:

- the work is carried out by an authorised competent person

- an attendant is at the emergency stop station

- the appropriate safe work procedure is in place.

Starting the conveyor

Before you start a conveyor, check that:

- no personnel are working on the conveyor, and that access platforms are clear (inspect the area to make sure)

- all the guards are fitted

- the emergency stop switches are working and marked

- lanyards are fitted and working correctly

- the warning siren is working

- firefighting devices are in place and ready for use

- all the lights are working and clean.

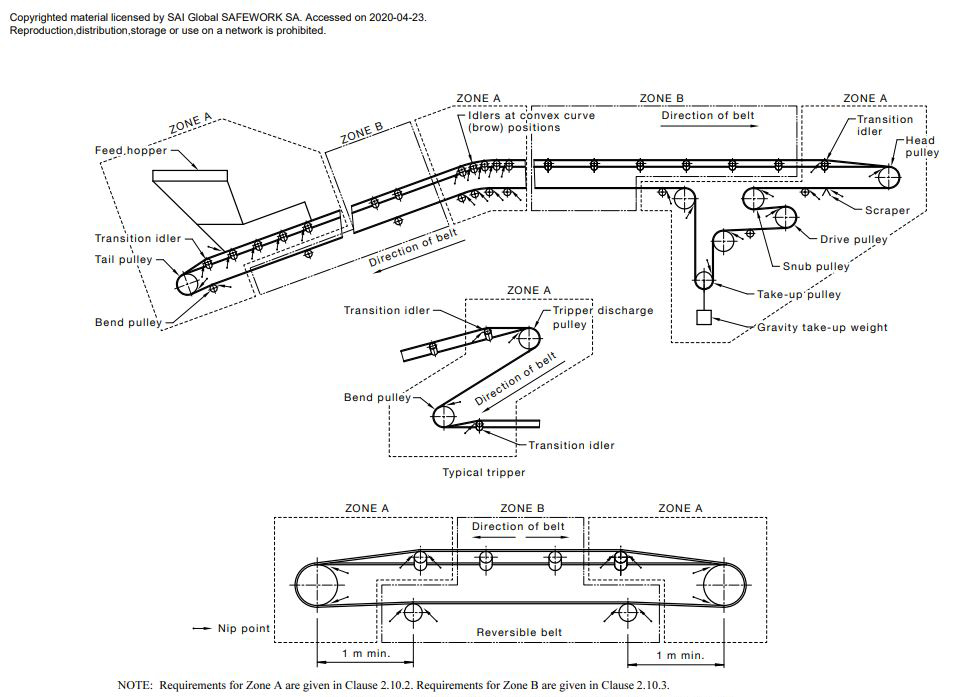

Nip points

The most important danger points on belt conveyors are the nip points marked with arrows.

Further information

AS/NZS 4024.3611:2015 : Safety of machinery - Conveyors - Belt conveyors for bulk materials handling - available from our Library